In recent years, the age-old craft of noodle making has seen a significant transformation with the introduction of automated noodle making machines. Whether you’re a home cook seeking convenience or a restaurant chef chasing efficiency, these machines have revolutionized the way noodles are prepared and served.

What Is a Noodle Making Machine?

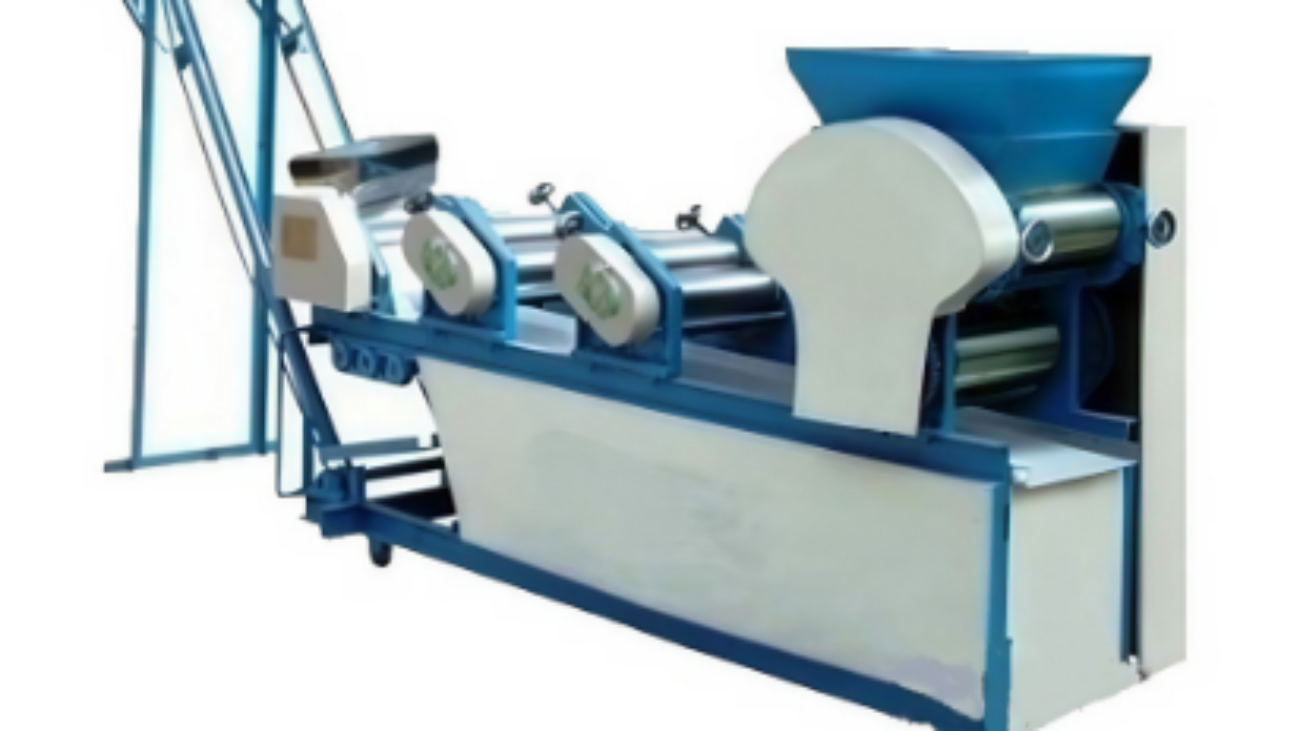

A noodle making machine is a device designed to mix, knead, roll, and cut dough into noodles of various shapes and sizes. These machines range from compact models for home kitchens to large-scale industrial equipment used in commercial food production.

How It Works

The process of making noodles with a machine typically involves three key stages:

- Mixing and Kneading: Flour and water (and sometimes eggs or other ingredients) are mixed to form dough. The machine kneads it evenly, mimicking the traditional hand-kneading method.

- Rolling and Pressing: The dough is then flattened into sheets of the desired thickness.

- Cutting: Blades cut the dough into noodles. Different attachments allow for various noodle types like spaghetti, udon, fettuccine, or ramen.

Some high-end machines even offer automatic drying or steaming features, making the process nearly hands-free.

Types of Noodle Making Machines

- Manual Machines: Operated by hand, these are perfect for traditionalists or hobbyists.

- Electric/Home Use Machines: User-friendly and compact, ideal for daily use in households.

- Commercial/Industrial Machines: Designed for bulk production, often used by restaurants, noodle shops, and food factories.

Why Use a Noodle Making Machine?

- Time-Saving: Reduce noodle prep time from hours to minutes.

- Consistency: Achieve uniform texture, thickness, and length every time.

- Customization: Make noodles with different flours (whole wheat, rice, buckwheat) and add your own flavors or colors.

- Hygiene and Efficiency: Especially in commercial settings, machines help maintain food safety standards.

Choosing the Right Machine

When selecting a noodle maker, consider:

- Capacity: How much dough or noodles can it handle per batch?

- Ease of Cleaning: Removable parts or non-stick surfaces make maintenance easier.

- Attachments and Settings: Look for adjustable thickness and various blade types.

- Durability and Build Quality: Stainless steel bodies and robust motors are ideal for heavy use.

Final Thoughts

Noodle making machines blend tradition with technology, enabling anyone to enjoy fresh, handmade noodles without the mess or effort of doing it all by hand. Whether you’re crafting homemade ramen or supplying a bustling noodle shop, there’s a machine out there to meet your needs.

Cart is empty

Cart is empty